Formulation of Suppository

Suppositories are prepared by rolling (hand-shaping), molding (fusion), and cold compression method.

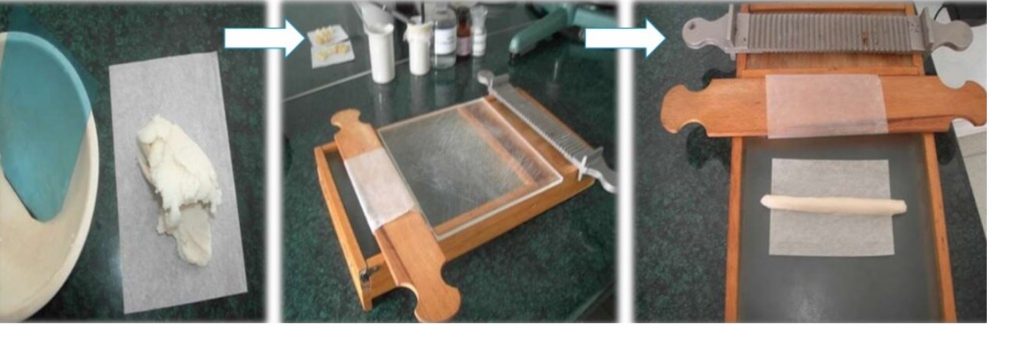

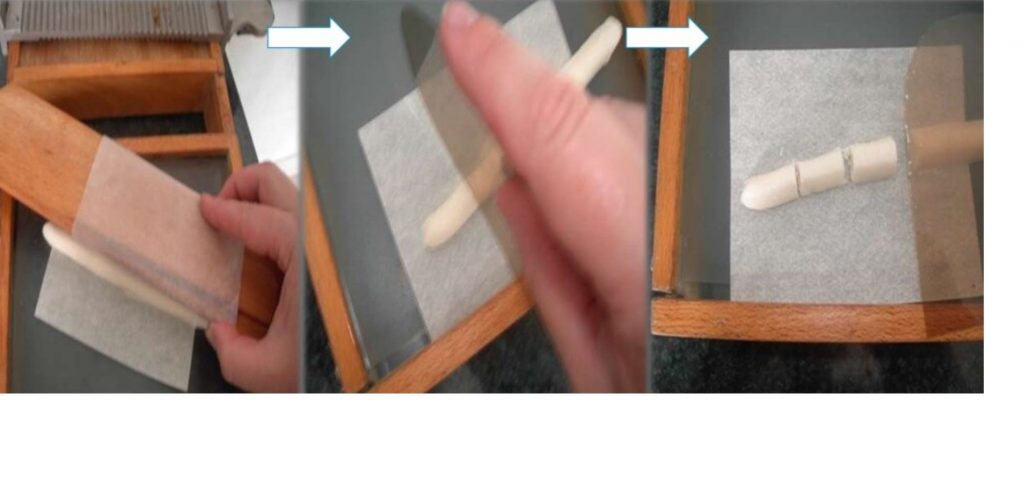

1.Rolling (hand-shaping) method

1. Rolled (Hand-Shaped) Method:

This is the oldest and the simplest method of preparing suppositories. The manipulation requires considerable skill, yet avoids the complications of heat and mold preparation. Suppository base with medicament is rolled with the hand & the desired shape is given.

Take the prescribed quantity of the medicinal substances and a sufficient quantity of theobroma oil/suppository base. The correct amount of grated theobroma oil then is added, and a mass resembling a pill is made by thoroughly incorporating the ingredients with a pestle. When the mass has become plastic under the vigorous kneading of the pestle, it quickly is loosened from the mortar with a spatula, and then transferred with the spatula to a piece of filter paper that is kept between the mass and the hands during the kneading and rolling procedure. By quick, rotary movements of the hands, the mass is rolled to a ball, which immediately is placed on a pill tile. The kneaded mass is rolled between fingers into rod-shaped units. The rods are cut into pieces and then one end is pointed with the help of spatula.

The suppository “pipe” or cylinder tends to crack or hollow in the center, especially when the mass is insufficiently kneaded and softened.

2. Compression-Molded (Fused) method

This method is suitable for thermolabile & insoluble drugs because heating of the base with medicament is not required.

The cold mass of the base containing the drug is compressed into suppositories using a hand-operated or power-operated compression machine. The suppository mass, such as a mixture of grated theobroma oil and drug, is forced into a mold under pressure, using a wheel-operated press. The mass is forced into mold openings, pressure is released, and the mold removed, opened, and replaced. On a large scale, cold-compression machines are hydraulically operated, water-jacketed for cooling, and screw-fed. Pressure is applied via a piston to compress the mass into mold openings.

3. Fusion or Melt Molding method

The suppository base is melted, then the drug is dispersed or dissolved in the melted (hot) suppository base. The mixture then is poured into a lubricated suppository mold, allowed to cool, and the finished suppositories removed by opening the mold.

Suppository molds are available for the preparation of various types and sizes of suppositories. Molds are made of aluminum alloy, brass, or plastic and are available with anywhere from six to several hundred cavities.

This is the method of choice for commercial suppository production (the most common method).

Types of Suppositories and various suppository base

Join WhatsApp channel to get latest Job notification, Study material, Previous paper, MCQ quiz, Admission alerts & News etc. for Pharmacy aspirants.

Subscribe our Telegram channel for Pharmacy Notes, MCQ Quiz, , Previous paper, Admission alerts & News etc. for Pharmacy professionals.

Join Telegram group for all Pharmacy books, Pharmacopoeia (IP, USP, BP), Pharmacy Notes, Previous Year Question papers in pdf format.